Over decades of operations, large nuclear power plants have proven their role in the clean energy landscape. Smaller plants developed over the same period have struggled to deliver an economically viable solution.

Small Modular Reactors (SMRs), designed within the framework of a new generation of nuclear power technology, are built differently. They are more precise, reproducible and versatile than their predecessors, and are now ready to be a critical component of the worldwide effort to achieve stable, sustainable power.

A History Filled With Challenges

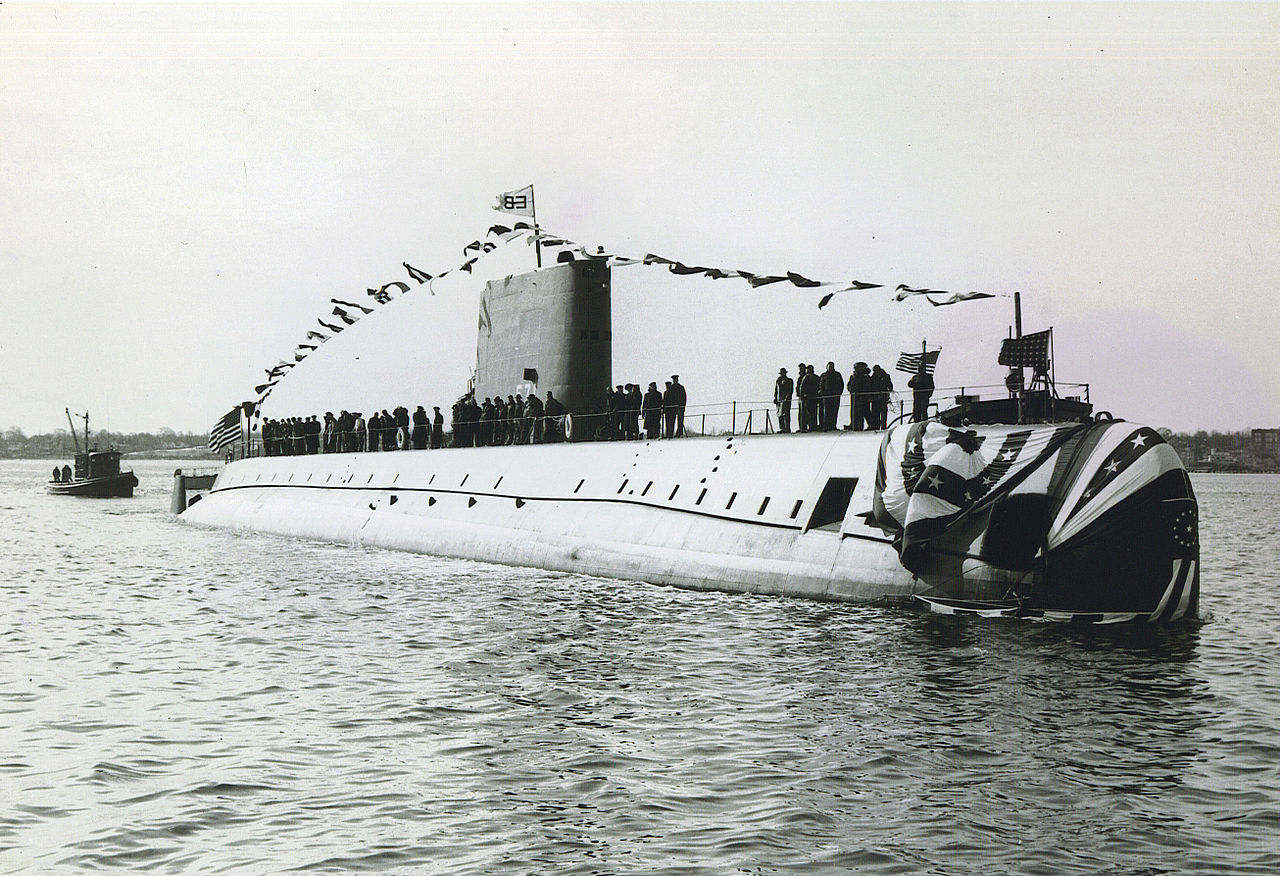

The concept of small reactors (under 300 MWe) began with naval propulsion in the 1940s. Engineers successfully designed compact, reliable power systems for nuclear submarines and ships. This successful military application led to the first civilian nuclear plant, the Shippingport Atomic Power Station, which began operation in 1957.

However, the history of early civilian small reactors is marred by poor economics. Many small-scale projects in the U.S. and globally were abandoned or retired early. These small power stations suffered from a fatal flaw: they were unable to compete with the economy of scale achieved by massive 1,000 MWe reactors. They carried all the complexity and cost of nuclear regulation but produced too little electricity to be profitable, leading to failure.

Defining the Nuclear Generations

The nuclear industry categorizes reactor designs into generations to mark phases of technological advancement.

Generation I reactors were the early prototypes from the 1950s and 1960s such as Shippingport. Their purpose was primarily to demonstrate the feasibility of electricity generation.

Generation II reactors defined the large-scale commercial fleet of the 1970s and beyond, such as standard Pressurized Water Reactors (PWRs). These large plants rely on active engineered safety systems that need external power and operator action during an emergency.

Generation III and III+ reactors represent evolutionary improvements, focusing on enhanced fuel performance and high standardization. They are distinguished by incorporating passive safety systems, which use natural forces like gravity or natural circulation to cool the core without external power. This was a significant step forward in safety and design standardization.

The Generation IV Leap

Generation IV designs are more than just a natural evolution of nuclear reactors. The term originated with the Generation IV International Forum (GIF), an international collaboration started in 2000. The forum defined the research necessary to move beyond the technology and limitations of the previous generations.

The GIF established four overarching goals that define Gen IV systems: Sustainability, Safety and Reliability, Economics, and Proliferation Resistance. Gen IV reactors must maximize fuel utilization, minimize waste, and achieve a clear life-cycle cost advantage over other energy sources. To meet these goals, designers have looked beyond light-water technology toward new coolants. Modern designs use materials like liquid sodium, lead, helium, and molten salts.

Crucially, these advanced coolants allow the reactors to operate at extreme temperatures, sometimes up to 1,000°C. This ultra-high heat is the key to unlocking the true strategic value of Gen IV technology: non-electric, industrial applications.

Why SMRs Succeed Now

The convergence of global demand and technological maturity represents a phase shift that overcomes the earlier shortcomings of small reactors.

As electricity consumption continues to grow, so does the desire to meet climate goals. At the 2023 United Nations Climate Change Conference (COP28), over twenty nations pledged to accelerate the growth of nuclear power.

SMRs, like all nuclear plants, produce zero emissions during operation, making them a powerful tool for decarbonization. SMRs also strengthen intermittent renewable energy sources by providing baseload power on calm or cloudy days.

Advanced manufacturing tools and processes also promise better outcomes for producing standardized modules in factories. Components can be built with stronger materials and higher precision, minimizing volatile on-site construction costs and manufacturing defects.

Gen IV systems will also be more economically viable as they produce more than just electricity. The high quality heat generated by these facilities can be used for district heating, water purification, hydrogen production and more. These can help to decarbonize industries such as mining or to reduce the cost of living for host communities.

While many locations could benefit from an SMR, they are an especially valuable option for remote communities. In these areas, electricity costs are already high due to diesel transportation and logistics. SMRs offer a versatile, long-lasting, and cleaner alternative that creates resilient power and local jobs.

The past is filled with important lessons, but it does not predict the future. Today’s SMRs are purpose-built with modern technology for a world that needs clean and reliable energy.